Categories

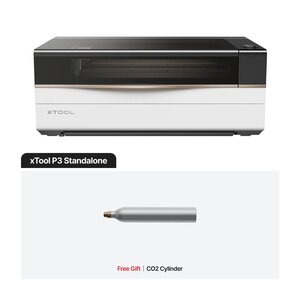

- xTool Laser- en Cutting machines

-

Silhouette America (All)

- New items

- Machines

- CAMEO PRO MK-II

- Cameo 5 & Accessories

- Cameo 5 PLUS & Accessories

- Portrait 4 & Accessories

- Curio 2 & Accessories

- Cameo 4 Pro Accessories

- Cameo 4 PLUS & Accessories

- Cameo 4 Accessories

- CAMEO 3/2/1 Accessories

- PORTRAIT 1/2/3 Accessories

- CURIO I Accessories

- 3D ALTA Accessories

- MINT & Accessories

- Software & Digital

- Blades & Mats

- Tools & Accessories

- Totes & Bags

- Special media

- Starter Kits

- Sketch Pens

- Cutting Fabric

- Silhouette Fabric Ink

- Tattoo Paper

- Rhinestones

- All Cutting machines & Accessories

-

Vinyl Adhesive

- PROMO VINYL

- Vinyl Kits

- Extra Tools

- Transfer Tape

- Monomer Matte Vinyl

- Monomer Glossy Vinyl

- Polymer Matte & Glossy Vinyl

- Neon Vinyl

- Glitter Vinyl

- Translucent Vinyl

- Deco Vinyl

- Holographic Vinyl

- Reflective Vinyl

- Mirror Vinyl

- Wood/ Carbon Vinyl

- Métallic Vinyl

- Stencil Vinyl/ Templates

- Frosted Vinyl

- Printable

- GITD Vinyl

- Magnetic Film

- Textile Flex Heat Transfer

- Textile Flock Heat Transfer

- Printable Flex & Toner Transfer FOREVER

- Other cutting materials

- Heat Press

- Printers (UV, DTF, Ghost White Toner, Eco solvent, Foil)

- Sublimation

- Blanco materials

- We R Memory Keepers

- Deco Foil, Gina K Designs & Scrapbooking

- Jacquard SolarFast (UV)

- Glass etching

- Mod Podge & Glues

- Candles & accesoires

- Stock Clearance CO2 laser - Machines Tools Materials

- Patchwork

Pages

Enlarged

Enlarged